What is inflow and Infiltration Costing You?

“Sewage overflows exert physical, chemical and biological effects on the receiving environment. This may result in human health, environmental and aesthetic impacts, which can be both acute and cumulative.“

– National Water Quality Management Strategy, Guidelines for Sewerage Systems Sewerage System Overflows November 2004. Natural Resource Management Ministerial Council

Figure 1 – Surcharging Sewer manhole

While the direct cost of treating stormwater that enters the sewerage network can be easily calculated, there are other less easily measured and less tangible costs due to I&I including:

- Increased siltation and the need to remove soil from sewers

- Increased blockages

- Loss of Network Capacity

- Capital outlay to cater for increased volumes & overflow storages,

- Accelerated degradation of sewer assets

- Higher wear and tear on pump station and treatment plant equipment

- Damage to road surfaces and other surfaces due to soil movement

- Poor public image

- Environmental pollution, costs of emergency clean-ups and ongoing reporting

- Public health risks

- Reduced productivity of personnel due to the need to react to and manage overflows

- Insurance and legal costs.

What is the Direct Cost of I&I?

The US EPA has estimated that 25-60% of all flow in sewage lines is due to I&I.

Further, a study by the US EPA found that manholes contributed to 30% of inflow and infiltration.

If we take just the 25% figure, then for a 10ML per day plant, this equates to 2.5ML per day due to I&I.

- At a sewerage operating cost of $1.93* per kL, this equates to $4,825 per day

- With manholes contributing 30% to I&I, the cost due to I&I through manholes for a 10ML per day plant is $1,447.50 per day or over $528,000 per year, every year.

* NSW Department of Energy Utilities and Sustainability – NSW Water Supply and Sewerage Performance Monitoring 2014/2015 Report, statewide median operating cost

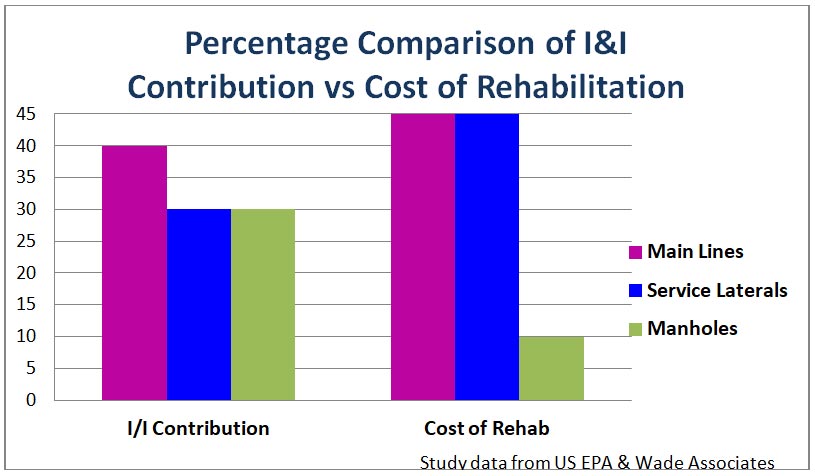

This same US EPA study also showed that manhole rehabilitation accounts for just 10% of rehabilitation costs, giving the quickest return on investment, while the cost of rehabilitation of pipes and laterals accounted for 90% of rehabilitation costs (see Figure 2 below).

Figure 2 Comparison of I&I Contribution v’s Cost of Rehabilitation

What does this mean?

The best bang for your buck is in treating the manholes.

You can quickly and cost effectively address I&I through the manhole chimney area allowing you to immediately start regaining network capacity and reduce the potential for sewer overflows.

The Return on Investment (ROI) by addressing I&I through the manhole means that the money spent implementing I&I control at the manhole chimney area is returned in a short time through reduced treatment costs and this saving quickly compounds over the life of the asset, reducing the burden on your budget and allowing you to do more with that budget.

What causes I&I to develop?

Leakage through the manhole frame – chimney area has been shown to be the single most significant source of inflow in the entire sewer system.

The reasons that manholes develop inflow and infiltration problems include:

• Differing expansion and contraction of metal frames vs concrete riser rings and sections resulting in rapid failure at joints

• Pavement expansion and contraction

• Settling and ground movement

• Poor construction methods and materials

• Traffic loading

Manhole covers can also be a significant source during rain events with open lift holes, poor fitting lids, worn or corroded surfaces and cracked or broken lids and surrounds.

Inflow through the manhole cover can be up to 20 litres per minute and even higher where manholes are situated in or near low lying areas such as in gutters, stormwater channels and creek lines.

How can we stop this from happening?

We can easily and cost effectively control I&I at the manhole with 2 approaches:

- By rehabilitation of the manhole chimney area.

- Preventative approach with new assets

Rehabilitation

Existing structures can be rehabilitated using Flex Seal Utility Sealant® (see Figure 3) & Aqua Seal® (see Figure 4)

- Flex Seal – a permanent method of sealing the riser rings/lid surround and joint sections inside a manhole with a state of the art urethane that achieves 800% elongation.

- Aqua Seal – a highly reactive two component urethane grout that will stop a 190 litre per minute leak in 3-5 seconds.

Figure 3 Flex-Seal Utility Sealant® Stops inflow through Joints

Figure 4 Aqua Seal Stops leaks and can be injected into flowing water

Prevention

We can prevent the development of I&I in new structures with positive external seals of frame and riser rings provided by Infi-Shield Uni-Band® (see Figure 5) and precast joints with Gator Wrap® (see Figure 6). While MH inserts (Figure 7) will stop inflow through the lid.

- InfiShield UniBand (Figure 5) – a one piece moulded high quality seal with non hardening butyl mastic to provide a flexible water tight seal around the top sections and riser rings of sewer manholes.

- Gator Wrap (Figure 6) – an EPDM rubber wrap with Butyl mastic adhesive (500% elongation) that easily wraps around the outside of sewer manholes, pipe joints, culverts and catch basins to provide a water tight seal & root barrier.

- Manhole Inserts – a strong & durable HDPE insert that sits below the MH lid and stops inflow through the lid.

Figure 5 – Infi-Shield UniBand® Seals Frame and Riser Rings

Figure 6 Gator Wrap® Seals Precast Joints

Figure 7 MH Insert Stops water inflow through the lid

When is the best time to start?

Now!

I&I is not going to go away or stop itself. Every day that it is left to continue contributes directly to higher sewerage operational costs, reduced network capacity and potential for overflows and increases the degradation rate of sewer assets and infrastructure.