Benefits of utilising inflow and infiltration control solutions

How can you benefit utilising ISC Services inflow and infiltration control solutions ?

1. Save Money with Reduced Operating Costs

2. Regain Network Capacity & delay capital upgrades

3. Reduce Sewer overflows and associated impacts

4. Improve Safety

Inflow and infiltration (I&I) of rainwater and groundwater into sewerage networks costs water authorities and rate payers in unnecessary transport and treatment costs, excessive degradation and wear of sewer assets and avoidable environmental impacts.

Sewer flows commonly increase 3 and 4 times average dry weather flows, are impacted even during small rain events and have even been reported as exceeding 10 times ADWF.

This creates a massive burden on the sewerage infrastructure, treatment plants and the people responsible for managing, operating and maintaining the network.

I&I steals network capacity, results in excessive pump operations and associated power consumption (and greenhouse gas burden), infiltration points will often allow soil, sand and silt to enter the network further reducing capacity and requiring costly desilting, accelerated asset degradation occurs through erosion while soil movement can allow structures to move resulting in cracking of structures, ground settling and subsidence and damage to roads and pavement.

Structures can also be damaged by vehicles and machinery with surrounds impacted by mowers and other machinery. New structures are also not immune to the problems of inflow and infiltration and are a significant source in an increasing problem.

“For new sewer systems, it is possible to significantly reduce inflow and infiltration by adopting improved or alternative approaches in the design and construction of pipes, appurtenances and maintenance structures. Investigations undertaken by Authorities into I/I in new developments have also indicated that a new sewerage system can be highly vulnerable in the period post sewer construction while building works are undertaken”

Increasing Predictability of Inflow-Infiltration Reduction Outcomes: Some Definitive Guidelines Steve Carne1* , Jaimie Hicks2 , Alton Whittle3 . 1 GHD Limited, Auckland, New Zealand, steve.carne@ghd.com 2 Water Services Association of Australia, Melbourne, Australia 3 GHD Inc, Harrisburg, Pennsylvania, USA

“Maintenance holes can also be a source of infiltration/inflow through defects in maintenance hole walls, displaced joints where pipes enter or leave these holes, displaced maintenance hole cones and surrounds, and cracked or missing maintenance hole covers”

National Water Quality Management Strategy, Guidelines for Sewerage Systems: Sewerage System Overflows November 2004. Natural Resource Management Ministerial Council

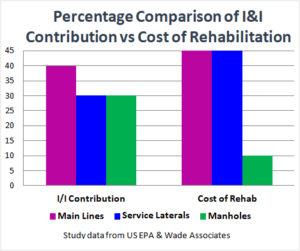

Studies by the US EPA show that 25-60 % of all sewage is from inflow and infiltration with 30% of this occurring through the manhole chimney area.

Addressing I&I at the manhole chimney area has been shown to provide the best return on investment with the cost of rehabilitation of the MH chimney area much lower while addressing a high source of I&I contribution.

What are the Benefits of addressing inflow and infiltration with ISC Services control solutions ?

- Established and proven solutions to inflow and infiltration

- Best return on investment to reduce I&I

- Solutions specifically developed and designed for purpose

- Reduced environmental impacts – reactive cleanup and reporting

- Extended life of assets

- Reduced operational costs

- Reduced wear on pump stations

- Reduced power consumption / greenhouse gas emissions

- Reduced failures and leaks in new constructions

- Improved public perception and confidence

- Delayed capital expenditure

- Reduced surface damage / road repairs

- Reduce the risk of manual handling injuries

Inflow and infiltration should be controlled using both prevention through best practice design and construction techniques as well as rehabilitation of existing structures with the range of infiltration control solutions available from ISC Services.

Prevention

You can prevent the development of I&I in new structures with positive external seals of frame and riser rings provided by Infi-Shield Uni-Band® and precast joints with Gator Wrap. While MH inserts will stop inflow through the lid.

- Infi-Shield UniBand – Specify Infi-Shield Uni-Band for all new constructions. A one piece moulded high quality seal with non hardening butyl mastic to provide a flexible water tight seal around the top sections and riser rings of sewer manholes.

- Gator Wrap – Specify Infi-Shield Gator Wrap on all new precast joints. An EPDM rubber wrap with Butyl mastic adhesive (500% elongation) that easily wraps around the outside of sewer manholes, pipe joints, culverts and catch basins to provide a water tight seal & root barrier.

- Manhole Inserts – a strong & durable HDPE insert that sits below the MH lid and stops inflow through the lid.

- Cretex Pro-Ring™ Lightweight yet trafficable grade adjustment system for sewer maintenance holes. Load tested to 240kN (equivalent of 24,679kg) and with a 25 year warranty nothing beats Pro-Ring™

Rehabilitation

Existing structures can be rehabilitated using Flex Seal Utility Sealant®, Aqua Seal, Internal Joint Seals and Pro-Ring™

- Flex Seal Utility Sealant – a permanent method of sealing the riser rings/lid surround and joint sections inside a manhole with a state of the art urethane that achieves 800% elongation.

- Aqua Seal – a highly reactive two component urethane grout that will stop a 190 litre per minute leak in 3-5 seconds.

- Chimney Patch & repair – CPR is a fibre reinforced, fast setting, high early strength acid resistant hand mixed and hand applied product for filling voids and repairing brick and concrete manholes and catch basins and will allow flow release within 15-30 minutes after placement .

- Cretex Pro-Ring™ can be used for new construction as well as raising existing sewer maintenance holes and stormwater catch basins to grade. The large range of heights available allows you to achieve an accurate grade without the need for shims or packers that can result in early joint or ring failure. Load tested to 22,679kg (222kN) and with a 25 year warranty nothing beats Pro-Ring™